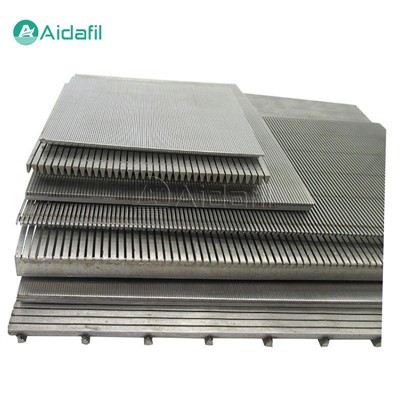

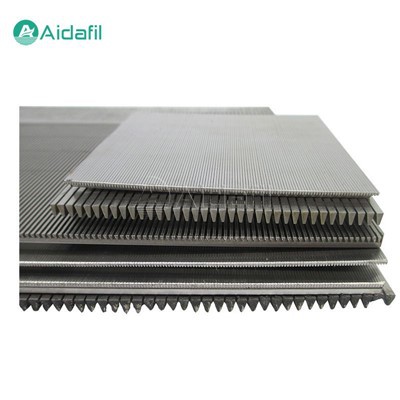

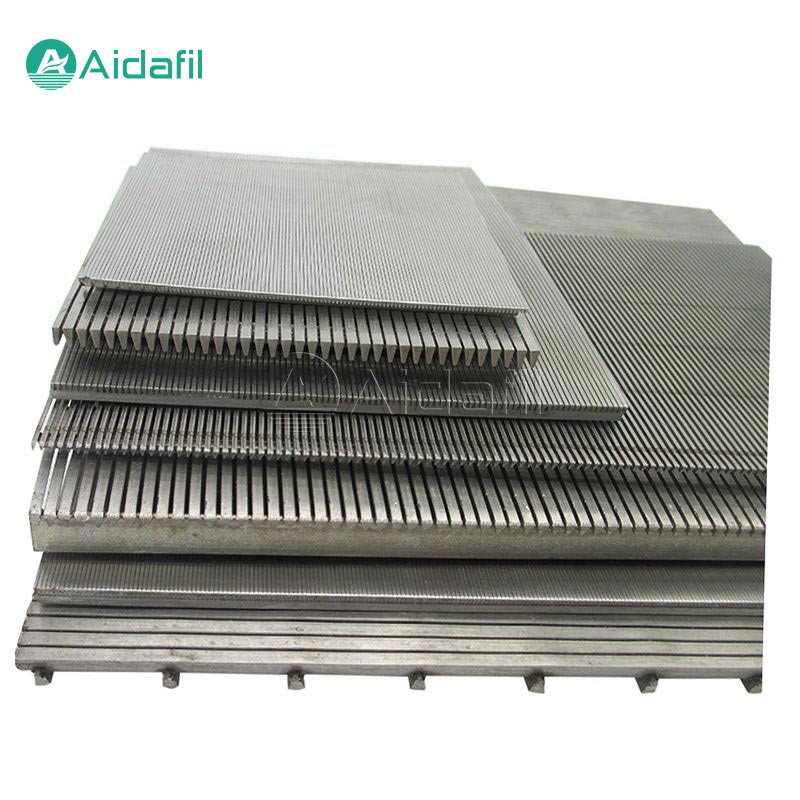

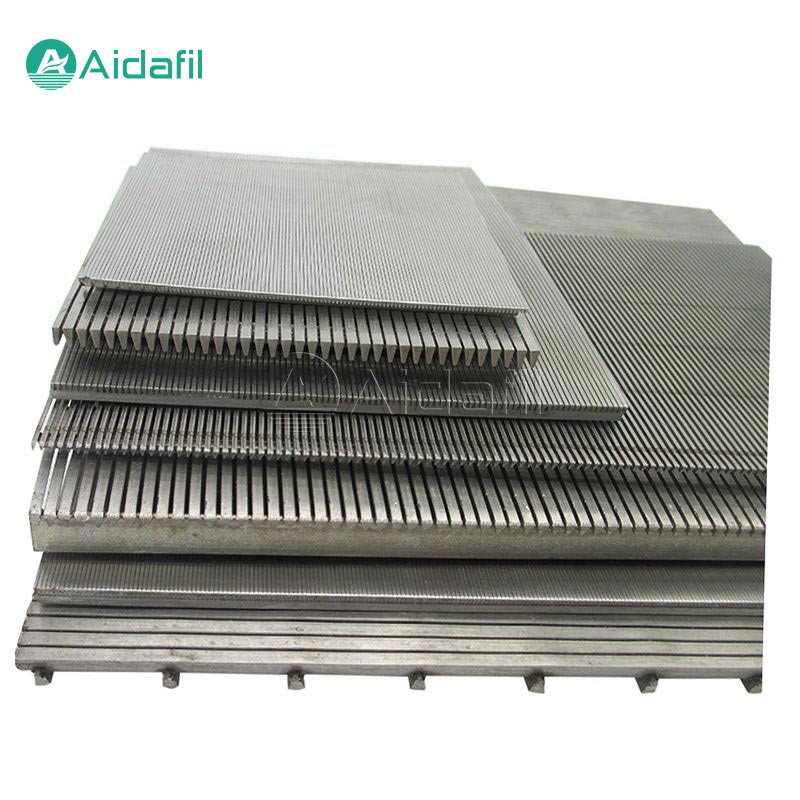

The high precision wedge wire screen mesh is mainly composed of wedge wire and support bar. The wedge wire is wound around the support bar at a certain angle to form continuous wedge-shaped pores, which constitute the filtration channel of the wedge wire screen mesh.

The high precision wedge wire screen mesh is a high-efficiency filter material widely used in liquid and gas filtration in industrial production. The core part of this screen mesh is wedge wire. The high precision wedge wire screen mesh not only has high filtration accuracy, but also has a strong structure and can work under high pressure and high temperature environment. In addition, its design makes cleaning and maintenance very convenient, so it has been widely used in many industries.

The high precision wedge wire screen mesh is mainly composed of wedge wire and support bar. The wedge wire is wound around the support bar at a certain angle to form continuous wedge-shaped pores, which constitute the filtration channel of the wedge wire screen mesh. When the fluid passes through these wedge-shaped pores, impurities are trapped inside or on the surface of the wedge-shaped pores, thereby achieving purification of the fluid.

The working principle of the wedge wire screen mesh is based on two mechanisms: screening and deep filtration. In the screening process, the screen mesh intercepts particles larger than the aperture; while in deep filtration, some smaller particles will penetrate into the wedge-shaped pores and be intercepted by the wedge wire fibers. This composite filtration method makes the wedge wire screen mesh have higher filtration efficiency and wider filtration range.

1. High filtration accuracy

2. Good pressure resistance

The high precision wedge wire screen mesh has a compact structure and strong pressure resistance, and is suitable for high-pressure environments. This makes it widely used in high-pressure process flows such as petroleum and chemical industries.

3. Easy to clean

4. Wide range of applications

|

Stainless steel 304, 316L, 904L, Hastelloy |

|

|

Minimum 0.015mm |

|

1. Water Treatment Industry

2. Petrochemical Industry

3. Pharmaceutical Industry

4. Food Processing Industry

1. Precise wedge wire manufacturing

- Advanced wire drawing technology

- Strict quality control

2. Stable wire winding process

- Automated wire winding

- Fine adjustment capability

3. Efficient welding technology

- Non-contact welding

- Perfect weld detection

4. Advanced surface treatment

- Environmentally friendly passivation

- Versatile coating technology

5. Strict quality inspection

- Comprehensive performance testing

- Precise dimensional measurement

6. Perfect production management system

- ISO certification

- Professional staff training

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

3. Corporate Vision:

4. Values:

· Team: Trust, responsibility, growth, win-win

Populære tags: